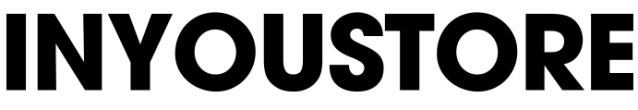

Wixey WR510 Electronic Digital Readout Kit for Portable Planers

Product information

Original price was: $72.99.$65.99Current price is: $65.99.

Description

About this item

- Fits most portable planers

- Easy to install, calibrate, and use

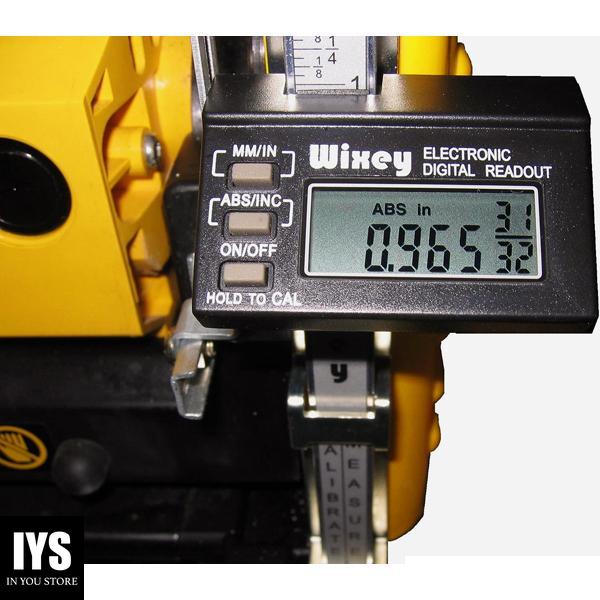

- Displays Inches with fractions or millimeters

- Large easy to read display angled for easy viewing

Product Description

Product Description

This precision gauge has an angled display for easy viewing as well as “auto shut off. ” And it fits most portable woodworking planers. It easily mounts to Dewalt, Delta, Ridgid, Ryobi, Makita, Craftsman, and others. It mounts in minutes and is calibrated in seconds. It displays the thickness of the wood coming out the back of the planer in inches with fractions or millimeters. It is easy to attach the WR510 to your portable planer. It comes with simple mounting brackets and detailed instructions that allow you to mount this on many models without even drilling a single hole. Calibration takes only seconds with its patented calibration system. The WR510 uses a piece of freshly planed board to ensure the readout displays the exact thickness of wood coming out the back of your planer. The large easy to read display reads in inches with fractions or millimeters. The fractions are displayed using “Precise Fraction Technology” which gives you 4 times the accuracy of other fraction readouts. The decimal inches are displayed in . 005-inch increments, the fractions in 1/32-inch, and the millimeters in . 1mm increments. Accuracy is . 0025 decimal inches, 1/500 fraction inches, and . 05mm metric. Once it is set up and calibrated, the WR510 consistently displays the thickness of wood coming out the back of your planer. It never needs re-calibrated unless the battery is replaced or the blades get worn down. Advanced features let you zero the blade, remove a precise amount of material, or measure the thickness of any board.

From the Manufacturer

This precision gauge has an angled display for easy viewing as well as “auto shut off.” And it fits most portable woodworking planers. It easily mounts to Dewalt, Delta, Ridgid, Ryobi, Makita, Craftsman, and others. It mounts in minutes and is calibrated in seconds. It displays the thickness of the wood coming out the back of the planer in inches with fractions or millimeters. It is easy to attach the WR510 to your portable planer. It comes with simple mounting brackets and detailed instructions that allow you to mount this on many models without even drilling a single hole. Calibration takes only seconds with its patented calibration system. The WR510 uses a piece of freshly planed board to ensure the readout displays the exact thickness of wood coming out the back of your planer. The large easy to read display reads in inches with fractions or millimeters. The fractions are displayed using “Precise Fraction Technology” which gives you 4 times the accuracy of other fraction readouts. The decimal inches are displayed in .005-inch increments, the fractions in 1/32-inch, and the millimeters in .1mm increments. Accuracy is .0025 decimal inches, 1/500 fraction inches, and .05mm metric. Once it is set up and calibrated, the WR510 consistently displays the thickness of wood coming out the back of your planer. It never needs re-calibrated unless the battery is replaced or the blades get worn down. Advanced features let you zero the blade, remove a precise amount of material, or measure the thickness of any board.

Shipping

We offer standard shipping within the United States. Currently, we do not offer international shipping.

- Your order will be processed within 2-5 business days.

- U.S. orders typically arrive in 4-5 business days with free shipping

*Delivery times may vary based on destination and customs.

Return & refund

You are entitled to cancel Your Order within 7 days without giving any reason for doing so.

The deadline for cancelling an Order is 7 days from the date on which You received the Goods or on which a third party you have appointed, who is not the carrier, takes possession of the product delivered.

In order to exercise Your right of cancellation, You must inform Us of your decision by means of a clear statement. You can inform us of your decision by:

- By email: [email protected]

- By visiting this page on our website: https://inyoustore.com/contact

We will reimburse You no later than 14 days from the day on which We receive the returned Goods. We will use the same means of payment as You used for the Order, and You will not incur any fees for such reimbursement.

Pack the unused item(s) you would like to return in the original packaging. We will issue a return label for you to send us back your product with the address at :

500 North Rainbow Blvd, Suite300

Las Vegas, Nevada, 89107

John Boldt (verified owner) –

The digital guage was very easy to install. Also if you have any questions you can YouTube it and there are numerous videos to help. It’s very easy to use and very accurate. I’m going to be putting one on my drum sander. I would recommend it for anyone that is concerned about product thickness when setting the planer depth.

April Marron (verified owner) –

This was simple to install, simple to setup, and changes the planing game instantly!

michael clim (verified owner) –

I installed this on my Harbor Freight planer. Took a whole 30 minutes including cutting a board to dial in the calibration thickness. It cut the first cut within .003 from the set point. I question anyone to tell me how that’s not advantageous and a time saver when using these lunchbox planers. The best thing about it is the first cut. No more running roller only passes waiting for cutter contact. Just mic your board and dial in the first removal. I had several options for placement and ended up mounting it (as most do) just to the right of the indeed apron. The unit has great visual clarity. Indicates decimal and fractional sizes when they are approached and decimal display only when in between fractions. I’m seriously considering a version from this maker for my table saw. This is definitely the most satisfying item I have bought recently for my woodworking shop. This device puts you in control of you planer instead of at its mercy. This will make so many operations commonly used after planing more accurate and time effective. Here is the way I use mine. I assemble my stack dado blade without shims to 3/4” and make the cut. Knowing that dado stacks are by design not going to be dead on without shims, I don’t let that become an issue, I just dial in my planer and cut the board to a perfect fit. These devices give confidence and options! If attention is paid to mounting, the infeed table will still fold without interference. As you can see in pictures, the scale could still be used without even turning the unit on if need be.

Jon Bouley (verified owner) –

Instructions I must offer for installing on my Dewalt DW734 were not very good. They could improve the pictures and descriptions. After the first few steps I really just looked at the unit and the hardware and pieced it together on my own. I do like the unit. I have tested it with a few pieces of Rock Maple and African Sapele. It seems to me accurate down to around to 1/100th of an inch or just under. I might be able to calibrate it a little more to get it even close to dead on. I cross referenced the thickness’s with a pair of digital calibers. I was taking about a 1/100th off at a time and it was pretty damn close. I do kind of wish it was designed so it could be secured with a screw some where on the unit. I am not a huge fan of double sided tape. I dont care how strong the tape is with changing temperatures and humidity levels the tape will eventually fail. Including maybe a bracket that is specific to each brand or model of planer could help solve this issue. The manual says you can drive some self threading screws into the case of your planer but my planer is brand new and I dont want that to void my warranty. I think I will find this to be very useful and much easier to read then the readout that the planer came with. I think it will be amazing for when I am going to make end grain butcher block counters because I will have to glue up the counters in sections with not having a planer that can handle over 20 inches. If i can get this down to each section being within a 1/100th of an inch of each other that would be amazing. The sanding of the final glue joint will be very quick and easy to level it out. Pretty excited to play around with it.